Are you running on a chemical or pharmaceutical method industry? Or do you have got experience running in fabric production? In case you do, perhaps you already know Ball Valve Manufacturers are components of zone turn valves or rotary valves. By way of turning a cope with that is connect to a ball that is in the valve, the valves open. They then flow in response to fluid or mechanical stress.

Inside the valve, there’s a ball that has a port, that is truely a hole on the middle. When this hollow is align with each valve ends, liquid can float effortlessly through it. After the valve has been close, the hollow turns into perpendicular to the valve ends impeding the waft of liquid.

Lots of various industries make use of ball valves with the intention to manipulate fluid. A number of these industries are oil and fuel manufacturers, chemical and petrochemical manufacturers, paper manufacturers, the textile manufacturing, energy vegetation, metallic manufacturers, prescription drugs processing and water and sewage flora.

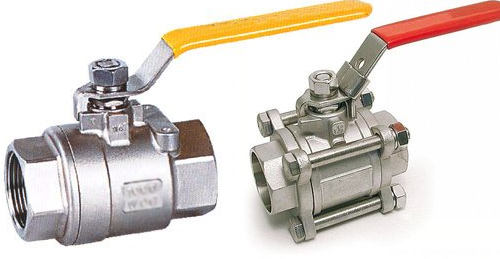

There are varieties of ball valves: the whole port and the standard port. A full port ball valve makes use of an oversize ball so that you can allow unrestricted glide. The size of the ball and the pipeline are same, so this has a decrease loss of friction. A widespread port, however, has a slightly controlled flow and makes use of a smaller ball. This ball is smaller than the pipeline, and it additionally has a smaller port. The valve’s pipe is one pipe size larger than the same old port wherein the liquid flows.